Index A-Z - Onboard-Tech

24M ABF ACC ADDEN Energy Addionics AESC Agratas Amprius Amte Power Anaphite BAK Battery Basquevolt Battrion Beyonder Blue Current Blue Solutions Britishvolt BYD CALB CATL Cellforce Group Cuberg Customcells Desten ElevenEs E-Lyte Enertech Enevate Envision AESC EPS – Electric Power Systems Eurocell EVE Energy Factorial Energy Farasis Energy Feon Energy Freyr Battery Gelion Gotion Hitech Group14 Technologies Gus Technology Ilika iM3NY Innolith Inobat Ion Storage System Ionblox Italvolt LG Energy Solution Lyten Molicel Morrow Batteries Nanograf Northvolt One OneD Panasonic PowerCo Prime Planet ProLogium QantumScape Sakuu Samsung SDI SES AI Sila Nanotechnolgies Siro SK on Solid Power Solidion Technology Solithor Soteria Big South 8 Technologies StoreDot Sunwoda SVolt Talent New Energy Theion Verkor Volexion WeLion Westmidlands Gigafacory Zenlabs Zeta Energy

US start-up for cell production technologies, founded in 2015. The underlying processes were developed in research projects at MIT [1], and the company currently has 200 employees [2].

The process is marketed as “24M ETOP™.” These are electrodes for Li-Io cells that can be integrated directly into a battery pack, eliminating the need for individual cells and modules. The packs can be flexibly configured and manufactured in different sizes to maximize efficiency and performance.

The business model is based on licensing the production process, with Kyocera among the first licensees. The Japanese technology group has also explicitly stated that it will use 24M technology in its energy storage systems (ESS), among other things.

Volkswagen is also a licensee, and PowerCo, the VW subsidiary responsible for the production of the “VW unified cell,” mentions 24M as a technology partner in a promotional film. It remains to be seen whether the 24M process will actually be used by PowerCo in the series production of the standard cell [3].

Other licensees include FUJIFILM Corporation (Fujifilm) and cell start-ups such as Freyr.

Unfortunately, the details of how 24M’s production process works are not explained. It can be assumed that the major Asian cell manufacturers such as CATL, BYD and LG will not allow themselves to become dependent on the cell production technology of a foreign manufacturer, as this is extremely competitive.

24M has now added further technologies to its portfolio, including:

- In March 2024, 24M introduced the “Liforever™” recycling process, which enables the direct reuse of cathode and anode materials without energy-intensive intermediate steps.

- In addition, “Impervio” is a new type of separator being developed to prevent the growth of dendrites and thus increase the safety of lithium-ion cells. The separator communicates via a signal line to the outside if a short circuit has occurred in the cell. This can then be deactivated via the battery management system (BMS). The market launch is planned for 2026.

Sources

[1] https://24-m.com/ (Homepage, Access 28.09.2022, 05.07.2025)

[2] Personal communication Advanced-Automotive-Battery-Conference-Europe-2025 (24.06.2025)

[3] https://www.salzgiga.com/ (Access 28.09.2022)

[cs 28.09.2022, 09.10.2025, 05.07.2025]

ABF – American Battery Factory [↑] [↓] [⇑] [⇓]

US start-up for prismatic battery cells with LFP chemistry. ABF claims to produce the safest, longest-lasting, most reliable and most environmentally friendly batteries, with a target of 10,000 charging cycles (full charge and discharge). Critical raw materials such as cobalt and nickel are deliberately avoided.

In addition to creating jobs in domestic production, ABF wants to play a decisive role in fulfilling the climate protection initiatives of the federal and state governments and the national safety requirements “Made in USA”.

Planned customers include manufacturers of lorries, buses, tractors and construction machinery.

Sources

[1] https://americanbatteryfactory.com/ (Homepage, Access 05.09.2022)

[cs 05.09.2022]

Cell and HV battery manufacturer from France, created in 2020 as a spin-off from the French accumulator company Saft. Saft (Société des Accumulateurs Fixes et de Traction) was founded back in 1918 and is recognised as a global leader in the field of nickel-cadmium (NiCd) rechargeable batteries for industrial use. Saft has been part of the French oil multinational TotalEnergies since 2016 [1].

ACC’s shareholders are Saft, Stellantis, TotalEnergies and, since September 2021, Mercedes–Benz AG. The production of more than 2 million lithium-ion batteries per year is planned for 2030, which corresponds to a capacity of 120 GWh.

The customer for ACC cells is Stellantis [2], from the middle of the decade also Mercedes-Benz [3].

No more detailed information on cell formats or cell chemistry was found on the ACC homepage.

Sources

[1] https://www.acc-emotion.com/ (Homepage, Access 05.09.2022)

[2] https://de.wikipedia.org/wiki/Saft_(Unternehmen) (Access 05.09.2022)

[3] https://group.mercedes-benz.com/unternehmen/news/mercedes-benz-update-batteriestrategie.html (Access 05.09.2022)

[cs 05.09.2022]

US start–up for solid–state cells, founded in 2021 by employees of Harvard University. According to the company, it has developed a new type of lithium metal technology that enables 10,000 charging cycles and 3-minute fast charging [1].

Sources

[1] https://www.addenenergy.com/ (Homepage, Access 15.09.2022)

[cs 15.09.2022]

British start-up founded in 2018 by academic staff at Imperial College London. It was founded on the basis of research into the cause of the battery explosions in the Samsung Galaxy Note 7 smartphone. Its investors include the Austrian supplier Magna and since July 2024 also GM [1].

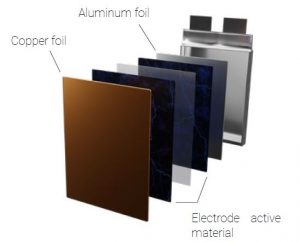

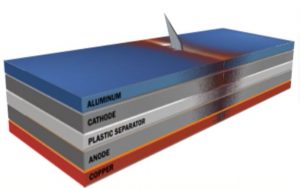

Addionics has developed a three-dimensional active material for both poles of lithium-ion cells. A 3D-structured copper foil was developed for the anode, which increases the surface area for the active material and improves mechanical stability. A 3D material in foil form was also developed for the cathode.

Structure of conventional Li-Io cell

(Mit freundlicher Genehmigung/Courtesy of Addionics Ldt. [White Paper April 2021])

Aufbau Li-Io-Zelle mit Addionics-3D-Material

(Mit freundlicher Genehmigung/Courtesy of Addionics Ldt. [White Paper April 2021])

The 3D material from Addionics replaces the copper collector and graphite foil for the anode and the aluminum collector and cathode foil for the cathode (see illustration).

The 3D material can be used for established cell types such as NCM and LFP, but also for more innovative variants such as solid-state cells and silicon/lithium-enriched cells. Pilot projects have been launched with various partners.

Sources

[1] https://www.addionics.com/ (Homepage, Access 07.03.2024)

[cs 07.03.2024]

AESC (Automotive Energy Supply Corporation) was founded in 2007 by Japanese car manufacturer Nissan and electronics group NEC as a joint venture for lithium-ion cells and battery systems.

In 2018, the Chinese company Envision, headquartered in Shanghai, acquired a majority stake in AESC, which is why the company was temporarily also known as Envision AESC. Envision describes itself as a green tech company that manufactures wind turbines and the associated IT systems for energy management, among other things [1].

In 2023, AESC was the world’s ninth largest manufacturer of traction batteries for electric cars [2]. As of December 2023, AESC batteries were installed in approximately 950,000 passenger cars. The company is proud of the fact that there has never been a critical incident such as a battery fire.

AESC has production sites in all Triad markets or is planning to establish them. These are located in North America (USA), Europe (UK, France, Spain) and Asia (China, Japan). In total, AESC plans to have a total capacity of 400 GWh in 2026.

The Renault-Nissan Group is one of AESC’s main customers as a result of the former corporate integration; cells and batteries from AESC are installed in the high-volume Nissan Leaf model, among others.

Other car manufacturers have been acquired as customers in recent years. In April 2022, AESC announced its intention to build a cell production plant in Bowling Green in Kentucky/USA with an annual capacity of 30 GWh. One of the customers is the Mercedes–Benz battery plant in Bibb County, Alabama/USA [3].

In October 2022, BMW announced that AESC will build a plant for round cells in the 46xx format in South Carolina/USA. This plant is also initially designed for an annual capacity of 30 GWh; the main customer will be the BMW plant in Spartanburg in the same state [4].

Sources

[1] https://www.aesc-group.com/ (Homepage, Access 24.10.2022)

[2] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 11.13.2023)

[3] https://media.mercedes-benz.be/de/naechster-meilenstein-der-mercedes-benz-elektro-offensive–neues-batteriewerk-fuer-produktion-des-eqs-suv-in-den-usa/ (Zugriff 24.10.2022)

[4] https://www.press.bmwgroup.com/deutschland/article/detail/T0404837DE/bmw-group-investiert-1-7-milliarden-us-dollar-in-die-produktion-von-elektrofahrzeugen-in-den-usa-und-nominiert-zellhersteller-envision-aesc-fuer-die-belieferung-des-us-werks-mit-batteriezellen?language=de (Access 24.10.2022)

[cs 24.10.2022, 19.12.2023]

Subsidiary of the Indian vehicle manufacturer Tata Motors. Agratas is to take over the production of lithium-ion cells and batteries for Tata Motors [1].

Production facilities are planned in India and England, and NMC and LFP cells in pristmatic format are to be produced.

Sources

[1] https://agratas.net/ (Homepage, Access 30.04.2024)

[cs 30.05.2024]

US start–up for innovative lithium–ion cells, which was founded in 2009 by materials scientist and Stanford professor Yi Cui and others [1].

Amprius develops cells with a silicon anode and uses extremely thin silicon wires with a diameter in the nanometer range. These so-called nanowires are intended to reduce the swelling of the silicon anode during the charging process. According to Amprius, it is the first cell manufacturer to commercialize lithium-ion cells with a silicon anode.

Amprius’ cells are already being tested by European aviation companies such as Airbus and BAE Systems and US institutions such as the Department of Energy and the US Army.

Pouch Cells from Amprius

(Mit freundlicher Genehmigung/Courtesy of AMPRIUS TECHNOLOGIES [Homepage])

Amprius produces pouch cells with a graviometric energy density of up to 450 Wh/kg and a volumetric energy density of up to 1150 Wh/l. The cells can be charged to 80 % SoC in less than 6 minutes.

Customers primarily include companies from the aviation sector, one of which produces high-flying, unmanned aircraft (HAPS = High Altitude Platform Station). In October 2023, Amprius announced that a leading eVTOL manufacturer had selected Amprius as its cell supplier. Unfortunately, it was not communicated which eVTOL producer this was.

Sources

[1] https://amprius.com/ (Homepage, Access 07.12.2023)

[cs 07.12.2023]

British start–up for lithium–ion cells, which was founded in 2013; Amte Power claims to be the only manufacturer of lithium-ion cells in the United Kingdom (UK) at present [1].

The company currently has a smaller production facility in Thurso in northern Scotland, and is now planning to open two additional factories in the UK with an annual capacity of 1 GWh. Even with this, Amte Power remains a smaller manufacturer compared to its Asian competitors [2].

There is no specific information on Amte Power’s customers on the homepage, only general information on the application areas of electromobility, energy storage systems (ESS) and special markets, with agricultural machinery shown as an illustration for the latter.

Amte Power is also working on sodium–ion cells. In May 2023, the company announced that Amte Power was the first European cell manufacturer to receive a UN certificate for the transportation of sodium-ion cells.

Pouch Cells from Amte Power

(Mit freundlicher Genehmigung/Courtesy of AMTE Power plc.[Homepage])

Cylindric Cells from Amte Poweer

(Mit freundlicher Genehmigung/Courtesy of AMTE Power plc. [Homepage])

Amte Power produces pouch cells and prismatic cells.

Amte Power is listed on the stock exchange (ISIN GB00BNQRZZ55, WKN A2QRD6).

Sources

[1] https://amtepower.com/ (Homepage, Access 07.12.2023)

[2] https://www.theguardian.com/business/2020/may/20/uk-first-car-battery-gigafactory-amte-power-britishvolt (Access 07.12.2023)

[cs 15.09.2022]

Anaphite is a start-up from Bristol that has developed an innovative production process for lithium-ion cells. The company was founded in 2018 by Alex Hewitt and Sam Burrow as a spin-out from the University of Bristol.

The technology combines active material, conductive additives and binders in a single, ready-to-use powder. To understand Anaphite’s innovation, you need to know how the production of lithium-ion cells works.

In the first production step, the electrodes are manufactured, i.e. the anode and the cathode. For this purpose, a viscous paste, known as slurry, is applied to a carrier film, which is then dried in ovens.

This drying phase takes several days and requires a lot of energy, which is why alternative coating processes have been researched for many years. One approach is so-called dry coating, in which the electrode material is applied to the carrier film as a dry powder.

Calendering of DCP® powder

(Mit freundlicher Genehmigung/Courtesy of Anaphite [Homepage])

This is where Anaphite’s process comes in: The start-up has developed a method with which the electrode materials are combined together in liquid form to achieve excellent dispersion and produce a well-structured powder. The highlight is that the liquid is removed in a low energy process to produce the dry powder, which can then be calendered directly onto the current collector.

The so-called DCP® powder (Dry Coating Precursor) can be processed without solvents and energy-intensive drying ovens and is said to reduce energy consumption by up to 30%. It reduces production costs by around 40% and saves space in cell production.

In 2024, the company raised USD 13.7 million in a Series A financing round to scale up its pilot production and further expand initial partnerships with battery manufacturers and automotive OEMs.

The goal is industrialization and market launch from 2028..

Quellen

[1] https://anaphite.com/ (Homepage, Zugriff 06.07.2025)

Chinese start-up that manufactures Li-Io Cells and energy storage systems (ESS). BAK Battery produces prismatic and cylindrical cells in the usual formats and with the known cell chemistry variants [1].

In particular, BAK Battery also produces sodium batteries in prismatic format [2].

We were unable to find any information on BAK Battery’s customer base on the homepage; according to ChatGPT 4.0, these include BYD, NIO, Geely und Xpeng.

Sources

[1] https://www.bakpower.com/ (Homepage, Access 04.06.2024)

[2] https://www.bakpowerproduct.com/category/45 (Homepage, Access 04.06.2024)

[cs 04.06.2024]

Spanish start–up for innovative lithium-ion cells, founded in 2022 by a consortium of investors in the Basque Country, initially 10 million was invested by the consortium. Solid-state batteries with a total capacity of 10 GWh are to be produced in 2027.

The aim is to develop a proprietary polymer composite electrolyte and an anode with a high silicon content. The technologies were developed at the neighboring Basque materials research institute CIC energiGUNE by Professor Michel Armand and his research group. The technologies are protected by 10 patents, all of which have been licensed to Basquevolt.

Michel Armand is a long-standing expert in the field of rechargeable battery technologies; in the 1970s, he was the first to describe the basic concept of today’s lithium-ion batteries, which is based on the exchange of lithium ions between the cathode and the anode..

Sources

[1] https://basquevolt.com/ (Homepage, Access 27.09.2022)

[cs 27.09.2022]

Attention, according to information from a Swiss financial portal, Battrion is in liquidation [1].

Swiss spin–off from ETH Zurich, working closely with the ETH Nanoelectronics Laboratory. Battrion develops innovative production technologies for the anode of lithium-ion cells, with which the microstructure of the anode is to be improved. In classic NMC cells, the anode is made of carbon. By improving one production step, Battrion has succeeded in improving the alignment of the carbon structure. As a result, the cell has a lower internal resistance and can be charged up to 50% faster.

For marketing, Battrion is cooperating with the German company Jagenberg, a specialist in mechanical and plant engineering.

Sources

[1] https://www.moneyhouse.ch/de/company/battrion-ag-in-liquidation-12722155121 (Access 09.12.2023)

[cs 05.09.2022, 09.12.2023]

Norwegian start–up for lithium–ion cells that was founded in 2016. On the one hand, Beyonder develops lithium-ion cells that can be charged 10,000 times in 8-12 minutes, according to the company.

On the other hand, the company is working on a combination of lithium–ion cells and ultracapacitors. The technical specifications of this product sound extremely promising; the cycle stability of 100,000 is orders of magnitude better than that of classic lithium-ion cells (1000 – 2000).

Applications include buffer storage for solar and wind parks (ESS) as well as storage for ferries and buses. The temperature resistance is adapted to the northern climate in Norway, although no specific limit temperatures are specified.

Beyonder attaches great importance to sustainable production and uses sawdust as a raw material for the active materials, among other things.

Pouch Cell from Beyonder

(Mit freundlicher Genehmigung/Courtesy of Beyonder [Homepage])

Battery Module from Beyonder

(Mit freundlicher Genehmigung/Courtesy of Beyonder Inc.. [Homepage])

Beyonder produces pouch cells and battery moduls.

Sources

[1] https://www.beyonder.no/ Homepage, Access 03.10.2022)

[cs 05.09.2022, 09.12.2023]

US start-up for innovative lithium-ion cells that was founded in California in 2014. Blue Current develops lithium-ion cells with a silicon-enriched anode and its investors include Koch Industries. The development goals are the highest possible energy density, a high level of safety and the lowest possible pressure within the cell [1].

Silicon-enriched anodes tend to expand greatly when lithium ions are stored in them. High pressure inside the cell is therefore one way of preventing the anode from expanding too much. Blue Current explicitly does not take this approach.

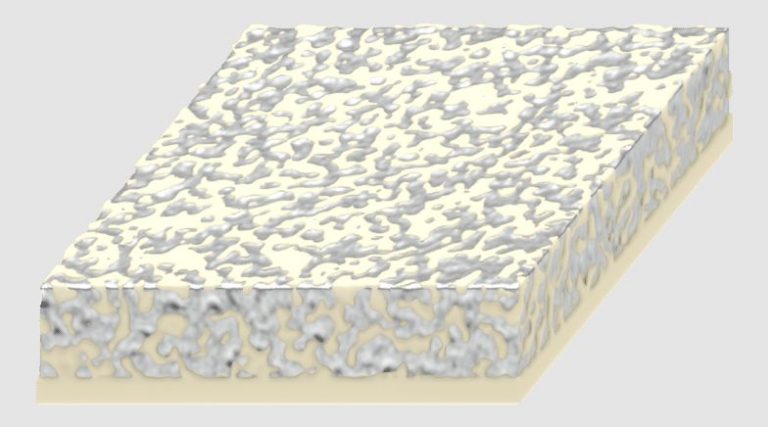

Composite material for encasing the anode active material (top)

(Mit freundlicher Genehmigung/Courtesy of Blue Current [Homepage])

Blue Current has developed a composite material to encase the anode active material (see illustration). This prevents the anode from expanding too much. Blue Current uses a polymer-ceramic combination as the electrolyte, with the polymers providing the elasticity and the ceramic providing the ion conductivity.

The first projects in the automotive sector have been launched, but no details are given.

Sources

[1] https://bluecurrent.com/ (Homepage, Access 10.03.2024)

[cs 10.03.2024]

Blue Solutions [↑] [↓] [⇑] [⇓]

Blue Solution is a subsidiary of the Bollore Group, a French conglomerate that was founded in 1822 as a paper factory. Blue Solutions describes itself as a pioneer of solid-state cells, as the company is the world’s first manufacturer to produce lithium-ion cells with non-liquid electrolyte [1].

Blue Solutions produces cells in pouch format as well as its own cell modules. According to Blue Solutions, it benefits from the parent company’s technological expertise in the production and coating of films.

The anode consists of a lithium metal foil, while the cathode is based on a lithium iron phosphate compound (LiFePO4).

A solid lithium polymer compound is used as the electrolyte, but this must be heated to a temperature of 50-80 degrees, as this is the only temperature range in which lithium ions can conduct [2].

Blue Solutions only markets cell modules with a corresponding heating device, i.e. not individual cells. The volumetric energy density at module level was 255 Wh/l in 2022 and is to be increased to 290 Wh/l by 2025.

Daimler Buses GmbH is one of the best-known customers in the automotive sector; according to unconfirmed sources, Blue Solutions is also in contact with Volkswagen [3].

In April 2022, the fire on two Bluebus 5SE city buses in Paris, both of which were equipped with Blue Solutions batteries, caused public attention.

Sources

[1] https://www.blue-solutions.com/en/ (Homepage, Access 06.06.2024)

[2] https://www.electrive.net/2021/03/03/wir-sind-der-eigentliche-pionier-der-feststoffbatterie/ (Access 06.06.2024)

[3] https://www.electrive.com/2024/01/16/volkswagen-considers-sourcing-solid-state-batteries-from-blue-solutions/ (Access 06.06.2024)

[cs 06.06.2024]

Attention. Britishvolt filed for insolvency at the beginning of 2023 and is currently being managed by the management consultancy EY. In mid-2023, Australian company Recharge Industries acquired Britishvolt to produce batteries for military, heavy commercial and stationary storage applications at the Northumberland site.

Australian energy company EDEA has also been in talks with Recharge to produce batteries for Australian military vehicles. However, according to BBC reports, members of Northumberland County Council still have doubts about Recharge’s ability to deliver the multi-billion pound facility. If no significant progress is made on site development by December 2024, there is an option to buy back the site [09.12.2023].

British start-up for lithium-ion cells, founded in 2019 by Swedish investors. Other investors have since joined the company, including Glencore and various UK funding providers [1].

The target market is the automotive industry, with round cells and prismatic cells mentioned as the cell format. A Gigaplant is being built in North East England (Northumberland) for cell production; the site has optimal access to the North Sea offshore wind farms and therefore to CO2-free energy.

The start of production is planned for mid-2025 [2] [04.10.2022].

Sources

[1] https://battery-news.de/2023/10/19/britishvolt-veroeffentlicht-plaene-zu-geplanter-zellproduktion/ (Access 09.12.2023)

[2] https://en.wikipedia.org/wiki/Britishvolt (Access 04.10.2022)

[3] https://www.britishvolt.com/ (Homepage, Access 04.10.2022)

[cs 04.10.2022, 09.12.2023]

BYD Company Limited (BYD for short) was founded as a Chinese start–up for battery cells in 1995 by Mr. Wang Chuanfu in the city of Shenzhen, with the abbreviation BYD standing for “Build Your Dream”. In 2003, BYD also became an automobile manufacturer when it acquired a stake in Xian Qinhuan Automobile.

The current BYD Group structure comprises various subsidiaries, the most important of which include BYD Auto, BYD Electronics, BYD LED and BYD Daimler New Technology Company, a joint venture between BYD and Mercedes-Benz AG [1]. You can read all about BYD Auto in our Index Street. In this onboard technology index, we focus on BYD’s cell and battery activities.

BYD is currently the only automotive company that develops and produces the lithium-ion cells, the modules and the battery pack itself. BYD uses all common cell formats – cell, pouch and prismatic – and uses the well-known chemical variants NMC and iron phosphate.

BYD is currently the world’s third largest cell manufacturer, but will very likely soon overtake LG Energy Solution in second place [2].

HV Battery from BYD with Blade Cells

(Mit freundlicher Genehmigung/Courtesy of BYD Company Ltd. [Homepage])

BYD attracted particular attention with the presentation of the Blade cell. This is a prismatic cell with an unusual length of almost one metre, which is visually reminiscent of a sword blade.

The blade cell has a lithium iron phosphate (LFP) chemistry which, in contrast to NMC chemistry, does not require critical raw materials such as nickel and cobalt and offers greater safety in terms of overheating (thermal runaway). An HV battery made from blade cells is said to last 1.2 million kilometres or 3,000 charging cycles, which is around three times better performance than NMC cells [3].

The disadvantage of iron phosphate cells compared to NMC cells is their lower energy density. When blade cells are used, this disadvantage is compensated for by the very compact design with which HV batteries can be assembled from blade cells.

According to various press reports, Tesla will use BYD’s blade battery in the entry-level version of the Model Y, which will be produced at the German plant in Grünheide near Berlin [4].

BYD is listed on the stock exchange, including in Frankfurt under WKN A0M4W9 and ISIN CNE100000296.

Quellen

[1] https://de.wikipedia.org/wiki/BYD (Access 10.10.2022)

[2] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 11.13.2023)

[3] https://battery-news.de/index.php/2021/03/16/neue-infos-zur-blade-battery-von-byd (Access 11.10.2022)

[4] https://insideevs.de/news/665817/tesla-model-y-batterie-byd (Access 11.12.2023)

[cs 11.10.2022, 11.12.2023]

CALB – China Aviation Lithium Battery [↑] [↓] [⇑] [⇓]

Chinese producer of lithium–ion cells, which was founded in 2007 in Luoyang in the Chinese province of Henan [1]. CALB is currently the seventh–largest cell manufacturer in the world [2] and ranked third among Chinese producers in 2022 [3].

CALB is planning to set up a European production facility in the port of Sines in Portugal. In the first step, an annual capacity of 15 GWh is to be realised by 2025, with a tripling of capacity planned by 2028[4].

CALB cells and batteries can be found in a large number of Chinese electric vehicles (BEV and PHEV), for example in models from Changan, Leapmotor, GAC Aion, GAC–Toyota, Geely, SAIC–GM–Wuling and XPeng [5].

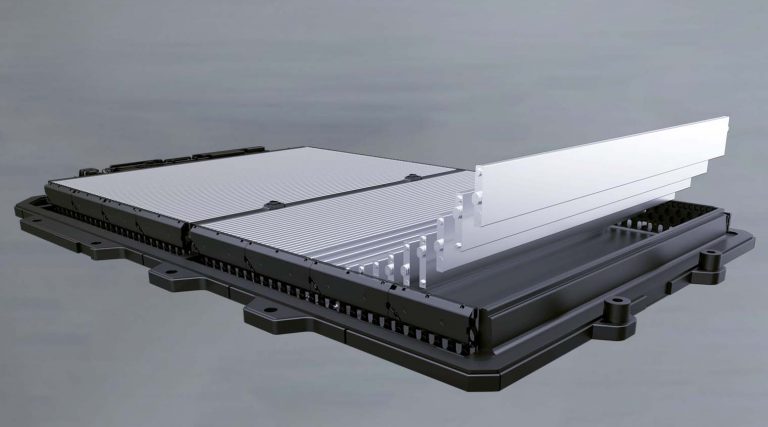

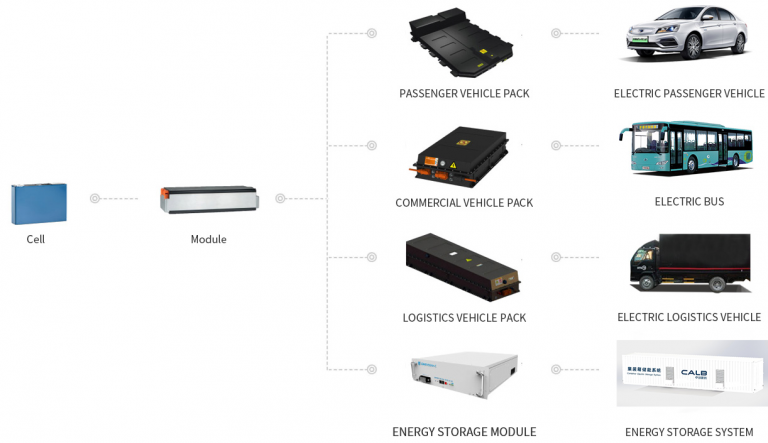

CALB Product Portfolio

(Mit freundlicher Genehmigung/Courtesy of CALB [Homepage])

CALB produces prismatic cells, the cell chemistry is based on the common variants NMC and LFP. CALB also manufactures modules and complete battery packs for cars, buses, lorries and storage systems (ESS) based on its own cells.

CALB presented a new type of cylindric cell at the China EV Forum 2023 in Beijing. This has the positive and negative poles on the same side and not opposite each other on the top and bottom as is usually the case. This arrangement means that currents no longer flow through the housing, which reduces the internal cell resistance by 50 per cent.

According to CALB, a charging rate of 6C is possible with this design, i.e. the cell can be fully charged in ten minutes. The round cell is to be produced with two cell chemistry variants. The NMC cell has a gravimetric energy density of 300 Wh/kg, while the LFP cell has a value of 230 Wh/kg. It is not known when this round cell will be produced and who the potential customers are [6].

Calb is a listed company and its shares are traded on the Hong Kong stock exchange, among others.

Sources

[1] https://de.wikipedia.org/wiki/CALB (Access 15.10.2022)

[2] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 12.12.2023)

[3] https://autonews.gasgoo.com/new_energy/70020806.html (Access 12.12.2023)

[4] https://battery-news.de/2022/11/07/calb-plant-zellfertigung-in-portugal (Access 12.12.2023)

[5] http://en.calb-tech.com/product/6/ (Homepage, Access 12.12.2023)

[6] https://efahrer.chip.de/news/laden-in-zehn-minuten-hersteller-zeigt-akkuzellen-mit-neuem-aufbau_1012347 (Access 12.12.2023)

[cs 15.10.2022, 12,12.2023]

CATL – Contemporary Amperex Technology Co. Limited [↑] [↓] [⇑] [⇓]

Cell start-up from China, founded in 2011 by Robin Zeng. In 2016, CATL was still in third place among the world’s largest cell manufacturers behind Panasonic and BYD, but then grew to become the world’s largest manufacturer of lithium–ion cells within just a few years. CATL produces at four sites in China – Liyang, Ningde, Xining and Yibin, with its headquarters in Ningde.

CATL currently has a global market share of 31% for lithium-ion cells, with a production volume of 200 GWh expected in 2023 [1]. CATL is planning an annual capacity of more than 500 GWh for 2025 and more than 800 GWh for 2030 [2].

Since October 2019, construction has also been underway at a German production site near Erfurt in Thuringia, which will have six production lines with a total capacity of 24 GWh when fully expanded [3]. A further European factory with a maximum capacity of 100 GWh is planned in Hungary [4].

CATL’s customers include premium manufacturers such as Mercedes–Benz AG as well as start-ups such as Nio, while other international customers include BMW, Honda, Hyundai, Stellantis (PSA), Tesla, Toyota, Volkswagen and Volvo. Customers on the Chinese market include AIC Motor, Foton Motor, Geely, GAC Group, SAIC Motor, Xpeng, Xiamen King Long, Yutong Bus and Zhongtong Bus.

CATL is involved in the BEV start-up Hozon Auto, and the cell manufacturer has founded the BEV joint venture Avatr with the state-owned Chinese car manufacturer Changan.

CATL Integrated Intelligent Chassis

(Mit freundlicher Genehmigung/Courtesy of Contemporary Amperex Technology Co., Limited. [Homepage])

CATL produces cells with NMC-811 and LFP chemistry, the cells are offered as pouch or cylindric cells. CATL also produces modules and packs, with its cell-to-pack technology (CtP) CATL achieves an energy density of 265 Wh/kg for the battery.

CATL is also working on a complete drive platform and is thus developing into a platform manufacturer. The so-called CIIC (CATL Integrated Intelligent Chassis) has a range of 1,000 km, a consumption of 10.5 kWh/100 km and a charging time of 300 km in 5 minutes. The first manufacturer to produce a complete vehicle based on CIIC is Hozon Auto [5]. This is hardly surprising, as CATL has a stake in the car manufacturer.

The news that CATL is working on sodium-ion cells, which are supposed to work without or with a small amount of lithium, caused a stir. The state-owned Chinese car manufacturer Chery is the first vehicle manufacturer to produce an electric car with a sodium-ion battery from CATL [6].

CATL is a listed company and its shares are traded on the stock exchange in Chenzhen and elsewhere.

Sources

[1] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 13.12.2023)

[2] CATL: Powering the Future of Electric Mobility – A Deep Dive into the Meteoric Rise of the World’s Leading Battery Giant (linkedin.com) (Access 15.10.2022)

[3] https://battery-news.de/2023/01/27/catl-plant-produktionserweiterung-in-thueringen (Access 13.12.2023)

[4] https://www.reuters.com/business/autos-transportation/chinas-catl-build-new-756-bln-battery-plant-hungary-2022-08-12 (Access 13.12.2023)

[5] https://carnewschina.com/2023/12/01/catl-developed-a-skateboard-chassis-with-a-1000-km-range-the-first-car-to-launch-in-2024 (Access 14.12.2023)

[6] https://twitter.com/catl_official/status/1647604699829518338?t=NQ7-dFUQhex6bvX5GIMz1g&s=03 (Access 14.12.2023)

[cs 15.10.2022, 14.12.2023]

Cellforce Group [↑] [↓] [⇑] [⇓]

Cellforce Group GmbH was founded in 2013 in Tübingen as a joint venture between Porsche AG and the company Customcells from Itzehohe in Schleswig-Holstein/Northern Germany. Originally holding a 72.7% stake, Porsche acquired Customcells’ shares in May 2023 and has been the sole owner of the Cellforce Group ever since. Interestingly, there was no press release from Porsche on this transaction.

Cellforce develops high performance lithium–ion cells with a silicon anode and the corresponding production technologies. Cellforce is very cautious about the technical details, but mentions a lower internal resistance and an increased temperature range of the Cellforce cell. There is no mention of who developed the technology for the silicon anode. With regard to the cathode, we assume that Cellforce uses the classic NMC technology.

Cellforce is currently building a new company site in Mahden, approx. 7km north-east of Reutlingen, Baden-Württemberg. A new development and pilot production site for battery cell technology is to be created, where cell chemistry will be researched and developed.

For cell production, Cellforce is cooperating with Dürr, which is primarily known as a supplier of painting systems. The US subsidiary Megatec has developed a process in which the material for the anode and cathode can be applied to a metal foil at the same time. Normally, the anode and cathode are coated sequentially, so Megatec’s process shortens the production process [2].

The reason for Customcells’ withdrawal is likely to have been the planned increase in capital, which will be necessary in connection with a significant expansion of production capacity. The Mahden production site is currently designed for an annual capacity of 100 kWh, which is sufficient for a small series of approx. 1000 vehicles per year (possibly Porsche Mission R).

According to press information, the Cellforce cell is so good that consideration is now being given to utilising it in higher-volume model series. To this end, the production volume is to be increased tenfold in order to equip the new generation of the Porsche Tycan with Cellforce cells, for example. Porsche currently uses cells from LG Energy Solution in the Tycan [3].

Sources

[1] https://www.cellforce.de/ (Homepage, Access 18.10.2022)

[2] https://www.automobil-produktion.de/produktion/cellforce-und-duerr-etablieren-neue-elektrodenfertigung-279.html (Access 15.12.2023)

[3] https://insideevs.de/news/674119/porsche-cellforce-ubernahme-batteriezellen (Access 14.12.2023)

[cs 15.09.2022, 14.12.2023]

US start–up for innovative lithium–ion cells, founded in 2015 in California by Richard Wang, acquired by Northvolt in 2021 [1].

Cuberg develops lithium-ion cells with a cathode in NMC technology and a lithium anode. In addition, there is an electrolyte that has been specially developed for this cell chemistry. The cells have an energy density of 380 Wh/kg and allow 672 charging cycles (residual capacity 80%).

The advantage of the technology is that the cells can be manufactured using established production lines.

Cuberg sees areas of application in both the automotive and aviation industries; a well-known customer of Cuberg cells is the eVTOL manufacturer Beta Technologies.

Pouch Cell and Battery Module from Cuberg

(Mit freundlicher Genehmigung/Courtesy of Cuberg, Limited. [Press Kit])

Cuberg produces cells in pouch format and also integrates them into modules and battery packs that comply with the relevant aviation safety standards.

Sources

[1] https://cuberg.net/ (Homepage, Access 18.10.2022)

[cs 27.09.2022, 19.12.2023]

Customcells is a spin–off from the Frauenhofer Institute in Itzehoe, Schleswig-Holstein, which was founded in 2012. As the name suggests, Customcells produces customised lithium–ion cells cells, whereby the company can draw on a very wide range of active materials for the anode, the cathode and the electrolytes. The range also includes more innovative active materials such as silicon-graphite anodes [1].

Customcells specialises in small or medium-sized cell series; if required, battery modules including BMS can also be produced from cells in small series. The design of the cells (pouch, cylindrical, prismatic) can also be freely selected by the customer [2].

Since March 2021, there has been a second Customcells site in Tübingen, Baden-Württemberg, with a similar range of services as in Itzehoe,

which is intended to cover the heavily industrialised south-west of Germany in terms of cell and battery requirements. Here, too, the focus is on customised series production of lithium-ion pouch cells according to customer requirements, i.e. small and medium series production of 10K to 1.2M cells “Made in Germany” with a long-term delivery guarantee [3].

In March 2023, the German eVTOL start-up Lilium announced that Custom-Cells had been selected as the cell supplier for the Lilium Jet. During cell production, the anode is to be pre-enriched with lithium in order to avoid capacity losses during the first charging processes. The underlying technology was developed by the cell technology start-up Ionblox [4].

Customcells itself announced a cooperation with the US cell technology start-up Enevate in December 2023. Custcells has concluded a licence agreement with Enevate, which provides for the use of XFC technology. This includes a silicon-based anode, a special electrolyte and a specific cell design [5].

Sources

[1] CUSTOMCELLS-Broschure_01.pdf (Homepage, Access 15.12.2023)

[2] https://www.customcells.de/ (Homepage, Access 18.10.2022)

[3] https://www.cct-batterien.de/ (Homepage, Access 18.10.2022)

[4] https://lilium.com/newsroom-detail/lilium-partners-customcells (Access 15.12.2023)

[5] https://customcells.com/customcells-collaborates-with-enevate-to-scale-up-advanced-battery-technology-globally (Access 15.12.2023)

[cs 18.10.2022, 15.12.2023]

Desten is a Californian start-up from Palo Alto that is working on fast-charging lithium–ion cells. The cell chemistry used is NMC and LFP, and the graphite anode is enriched with a nanomaterial. Desten develops all essential cell components itself [1].

Desten produces cells in pouch format, the cells can be charged from 20% to 80% in just under 4 minutes, the C-rate is said to be 10C.

Nothing is known about pilot projects in the automotive sector.

Sources

[1] https://desten.com/ (Homepage, Access 26.05.2024)

[cs 26.05.2024]

ElevenEs was founded in Serbia in 2019 and develops lithium-ion cells with LFP chemistry in prismatic format. The latest news on the homepage is from April 2023, which raises certain doubts about the company’s continued existence [1].

On a battery portal, however, there is a message from April 2024 stating that customers from the electric car, bus, truck and energy storage systems sectors will receive A and B samples [2].

Sources

[1] https://elevenes.com/ (Homepage, Access 11.06.2024)

[2] https://batterytechassociation.org/elevenes-opens-europes-first-lfp-battery-cell-manufacturing-facility/ (Access 11.06.2024)

[cs 11.06.2024]

E-Lyte Innovations GmbH is a German start-up that was spun out of Münster Electrochemical Energy Technology (MEET) in 2019. The company’s headquarters are now located in Kaiserslautern, but research and development are still based in Münster [1].

E-Lyte develops electrolytes for lithium-ion cells and is involved in a large number of national and European research projects.

One of its cooperation partners is the company Customcells.

Sources

[1] https://e-lyte.de/ (Homepage, Access 11.06.2024)

[cs 11.06.2024]

Enertech International [↑] [↓] [⇑] [⇓]

Enertech was founded in Korea in 2001 and develops lithium–ion cells, battery modules, complete battery systems and active materials for cell production. Enertech battery systems are used in the approx. 15 km long monorail railway in the city of Incheon, LG-Chem is a customer of active materials for the cathode [1].

According to its homepage, Enertech is also targeting electric vehicles with its cells and batteries, but we have not found any information on specific vehicle manufacturers.

Enertech has licensed the cell technology from Enevate, which is based on a silicon anode.

Pouch Cell and Battery-Module from Enertech

(Mit freundlicher Genehmigung/Courtesy of ENERTECH International Inc. [Homepage])

Enertech produces energy and power cells in pouch format. The company also manufactures modules and battery packs based on the cells.

Sources

[1] http://www.enertechint.com/ (Homepage, Access 20.10.2022)

[2] https://www.electrive.net/2021/06/10/batteriezellen-enertech-erwirbt-lizenz-von-enevate (Access 20.10.2022)

[cs 17.09.2022, 19.12.2023]

US start-up for innovative lithium–ion cells, founded in Irvine, California, in 2005. Enevate has been working on cells with a silicon anode for many years and has filed more than 400 patents worldwide. John Goodenough, one of the three Nobel Prize winners for the invention of the lithium-ion battery, was a technical advisor to Enevate for over ten years.

Enevate’s investors include the Renault–Nissan–Mitsubishi group of companies, LG Chem, Samsung, Lenovo and several investment funds.

The three core technologies that Enevate has been working on for many years are (1) the silicon anode, (2) the electrolyte and (3) the innovative cell design. Enevate’s cells are primarily aimed at improving fast-charging capability, making it one of the main competitors of the Israeli start-up StoreDot.

Enevate cells can be charged to 75% capacity in 5 minutes (at an outside temperature of 10 degrees) and achieve a gravimetric energy density of 350 Wh/kg and a volumetric energy density of 1000 Wh/l.

Pouch Celle from Enevate

(Mit freundlicher Genehmigung/Courtesy of Enevate Corporation [Homepage])

Enevate’s business model is based on licensing its technology; the German start-up Customcells and the Korean company Enertech International have acquired production licences.

Enevate itself produces pouch cells in small series in order to provide potential customers with cell samples. The company supports and advises licencees in setting up cell production, but Enevate does not appear to be aiming for its own high-volume production.

Sources

[1] https://www.enevate.com/ (Homepage, Access 19.12.2023)

[2] https://www.electrive.net/2021/06/10/batteriezellen-enertech-erwirbt-lizenz-von-enevate://www.electrive.net/2021/06/10/batteriezellen-enertech-erwirbt-lizenz-von-enevate (Access 21.10.2022)

[cs 19.12.2023]

EPS – Electric Power Systems [↑] [↓] [⇑] [⇓]

US start-up for powertrain components for electric aircraft, which was founded in North Logan, Utah, in 2016. Its investors include aircraft manufacturer Boeing and aviation supplier Safran.

Among other things, EPS produces battery systems for electric aircraft and has already implemented a large number of technology projects with various aircraft manufacturers. EPS installs supplied cells (pouch and round cells), i.e. EPS is not a cell manufacturer.

EPS’ customers and project partners include manufacturers of classic aircraft as well as vertical take-off start-ups such as Archer Aviation, Skydrive and Supernal Aero.

The battery systems from EPS are certified in accordance with aviation standards, i.e. they fulfil standards such as RTCA/DO-311A (Minimum Operational Performance Standards for Rechargeable Lithium Batteries and Battery Systems).

Powertrain Components from EPS

(Mit freundlicher Genehmigung/Courtesy of Electric Power Systems, Inc. [Homepage])

In particular, EPS also offers electronic components that enable the electrical disconnection of battery subsystems so that fault-tolerant battery systems can be realised.

Sourcen

[1] https://epsenergy.com/ (Homepage, Access 22.10.2022)

[cs 22.10.2022, 19.12.2023]

Attention: Since 2023, there are no new entries on the Eurocell homepage, Eurocell may have discontinued its European sites.

Korean start-up for lithium–ion cells and battery systems, founded in Korea in 2018. As the name suggests, Eurocell wants to set up a production facility for lithium-ion cells in Europe, which is currently scheduled to be built in the Netherlands by 2025.

Eurocell plans to produce power cells and energy cells, with an energy density of over 280 Wh/kg planned for the energy cells.

Sourcen

[1] www.eurocell.kr/ (Homepage, Access 25.10.2022)

[cs 22.10.2022, 19.12.2023]

Chinese start-up for lithium–ion cells and battery systems, which was founded in 2001. Based on its own cells, EVE Energy also supplies lithium-ion battery systems for the automotive market, namely for micro-hybrids (48V), mild hybrids, plug-in hybrids and BEV vehicles.

Eve Energy also produces 14V lithium-ion batteries as a replacement for the classic 12V lead-acid battery. In addition, Eve Energy also produces buffer storage systems (ESS) for the electricity market.

Alongside CATL, BMW has selected EVE Energy as a supplier for BEV models of the so-called New Class, which are to be launched on the market from 2025.

Cell, Module and Battery-Pack from EVE Energy

(Mit freundlicher Genehmigung/Courtesy of EVE Energy Co., Ltd. [Homepage])

Eve Energy produces pouch, prismatic and round cells with NMC chemistry; the prismatic cells are also available with LFP chemistry.

EVE Energy is one of the technology partners of the Israeli start-up StoreDot, which develops particularly fast-charging cells.

[1] https://www.evebattery.com/en (Homepage, Access 26.10.2022)

[2] https://www.press.bmwgroup.com/deutschland/article/detail/T0403470DE/… (Access 21.12.2023)

[cs 26.10.2022, 21.12.2023]

Factorial Energy [↑] [↓] [⇑] [⇓]

US start-up for innovative lithium–ion cells, which develops cells with lithium-enriched anodes; cooperation partners include Mercedes–Benz, Stellantis and Hyundai [1].

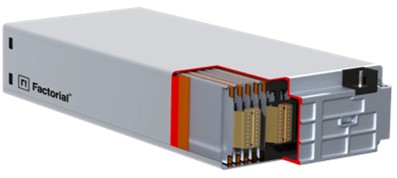

Factorial Energy is developing a semi-solid-state cell in pouch format, which should have a 20-50% higher energy density. In addition to the lithium anode, the start-up uses a self-developed semi-solid electrolyte called FEST (Factorial Electrolyte System Technology), which has an ignition temperature of 200 degrees. The fire risk of the FEST electrolyte is therefore significantly lower than that of commercially available electrolytes with a lower ignition temperature [2].

The start of production at Factorial Energy’s first high-volume cell factory was announced in October 2023. This is located near the development site in the Boston/Massachusetts area. According to the manufacturer, the factory has enough space for 200 MWh per year [3].

Pouch Cell from Factorial Energy

(Mit freundlicher Genehmigung/Courtesy of Factorial Inc. [Homepage])

Battery-Module from Factorial Energy

(Mit freundlicher Genehmigung/Courtesy of Factorial Inc. [Homepage])

The current development status is 40 Ah cells at room temperature, the target is 100 Ah cells. In October 2023, the first cell samples with 100 Ah were delivered to cooperation partners; Factorial has not communicated which companies are involved [4].

Production should essentially be possible using known processes and technologies; according to the manufacturer, only around 20% of the production process needs to be adapted.

In September 2024, Factorial Energy and Mercedes-Benz published more details about the cathode. This is based on a sulphur compound and can be operated at very high temperatures (approx. 90 degrees).

Production does not require a wet process, so time-consuming and energy-intensive drying steps can be omitted. Formatting of the cell, i.e. multiple charging and discharging in the final production stage, is also no longer necessary.

Factorial Energy has protected the overall technology under the trade name SolsticeTM. According to the company, an energy density of 450 Wh/kg is achieved, although it remains to be seen whether this value refers to the cell or the module.

Sources

[1] https://factorialenergy.com/ (Homepage, Access 04.10.2023)

[2] https://www.sae.org/news/2023/04/factorial-ss-battery (Access 04.10.2023)

[3] https://electrek.co/2023/10/23/factorial-energy-solid-state-battery-plant-largest-assembly-line-in-us (Access 26.12.2023)

[4] https://electrek.co/2023/10/05/factorial-energy-ships-samples-solid-state-batteries-to-automotive-partners (Access 04.10.2023, 26.12.2023)[5] https://www.businesswire.com/news/home/20240910561651/en/Factorial-Introduces-Solstice%E2%84%A2-an-All-Solid-State-Battery-with-Mercedes-Benz-as-a-Key-Customer-and-Development-Partner (Access 12.09.2024)

[cs 04.10.2023, 26,12.2023, 12.09.204, 12.09.2024]

Farasis Energy [↑] [↓] [⇑] [⇓]

Chinese start-up for lithium–ion cells [1], the company currently has a global market share of around 2% and ranks eighth among the world’s largest cell manufacturers [2].

The company is planning an annual production volume of 145 MWh for 2025 [3].

Mercedes–Benz has held a stake of around 3% in Farasis since 2020 [4], and other customers include Chinese vehicle manufacturers such as GAC Aion [5].

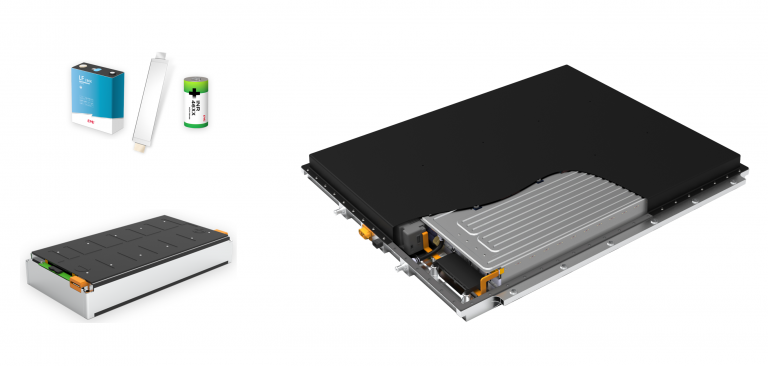

Cell, Module and Battery-Pack from Farasis Energy

(Mit freundlicher Genehmigung/Courtesy of Farasis Energy Europe GmbH [Downloads@Homepage])

Farasis produces pouch cells with NMC chemistry, and the manufacturer also produces battery modules and packs for electric vehicles based on these cells [6].

Sources

[1] https://en.farasis.com/ (Homepage, Access 04.10.2023)

[2] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 04.10.2023)

[3] https://www.farasis-energy.com/app/uploads/2023/12/Farasis_Produktbroschure-Battery-goes-orange_2023_WEB_EUR-1.pdf (Access 26.12.2023)

[4] https://www.handelsblatt.com/unternehmen/industrie/farasis-daimler-steigt-bei-chinesischem-batteriehersteller-ein/25973002.html (Access 04.10.2023)

[5] https://en.farasis.com/index/news-detail/infoid/284 (Access 04.10.2023)

[6] https://www.farasis-energy.com/app/uploads/2023/12/Broschure-Produktubersicht-Product-overview_2023_WEB_EUR-1.pdf (Access 26.12.2023)

[cs 04.10.2023, 26,12.2023]]

US start-up for innovative lithium–ion cells, which was only founded in 2022 by former Stanford University scientists in the Boston area of Massachusetts. Feon develops Li-ion cells with a lithium anode. To prevent dendrite formation, new molecules are used in the electrolyte that passivate the Li metal surface [1].

Pouch-Zelle von Feon Energy

(Mit freundlicher Genehmigung/Courtesy of Feon Energy, Inc. [Homepage])

According to Feon, its cells achieve an energy density of over 400 Wh/kg and production should be possible using established production technologies.

We are not aware of any specific pilot projects with companies from the automotive industry or other cell manufacturers.

Sources

[1] https://www.feonenergy.com/ (Homepage, Access 29.06.2024)

[cs 29.06.2024]

Norwegian start-up for lithium–ion cells that was only founded in 2018; fields of application are energy storage systems and electromobility [1].

Freyr is currently building a cell production facility in Mo i Rana in northern Norway, utilising semi-solid-state technology from 24M. This reduces the proportion of passive cell components and promises a higher energy density and simpler production processes [2].

Freyr is not an exclusive licensee of the 24M technology; other companies such as the VW subsidiary PowerCo have also licensed it.

As far as possible, all raw materials are to be obtained from Northern European sources in order to minimise the carbon footprint of cell production. The traditionally very high proportion of renewable energies in Norway is helpful here, with around 95% of the electricity being produced carbon-free using hydropower.

Freyr is listed on the stock exchange, e.g. in Frankfurt under WKN A3CT9J and ISIN LU2360697374.

Sources

[1] https://www.wallstreet-online.de/nachricht/15865557-freyr-battery-aktie-kommender-batteriegigant (Access 09.10.2023)

[2] https://www.freyrbattery.com/ (Homepage, Access 09.10.2023)

[cs 04.10.2023]

Australian start-up for innovative innovative lithium-ion cells, which was founded in 2015 as a spin-off from the University of Sydney. Gelion develops cells with a lithium-sulphur cathode and a liquid electrolyte developed in-house. The anode comes from the respective industry partner and is therefore not developed by Gelion [1].

The current state of development is sample cells in pouch format with 9.5 Ah and an energy density of 395 Wh/kg.

Gelion has agreed a development partnership with Glencore, the largest internationally active raw materials company.

Gelion is listed on the London Stock Exchange (WKN A3C8RH, ISIN GB00BNBQZD59).

Sources

[1] https://gelion.com/ (Homepage, Access 09.07.2024)

[[cs 09.07.2024]

Gotion High-Tech [↑] [↓] [⇑] [⇓]

Chinese start-up for lithium–ion cells, which was founded in 2006 in Hefei in Anhui province; fields of application are energy storage systems and electromobility [1]. The headquarters are now located in Silcon Valley in the USA, with other locations in Germany, the USA, Singapore and China [2].

Gotion’s customers include the Chinese car manufacturers BAIC, Changan, Chery, JAC, Leapmotor and Wuling.

VW has been the largest single shareholder since 2021 with a 26% stake. Gotion is also a technology partner of VW and is supporting the VW subsidiary PowerCo in setting up the cell production plant in Salzgitter, specifically with the factory layout, systems and production processes [3].

Gotion itself holds a 25% stake in the Slovakian start-up Inobat.

Gotion produces round cells and prismatic cells (VW) with different cell chemistry variants.

Gotion is listed on the stock exchange, including in Frankfurt under WKN A3CT9J and ISIN LU2360697374.

Sources

[1] https://en.gotion.com.cn/ (Homepage, Access 09.10.2023)

[2] https://www.gotion.com/ (Homepage, Access 09.10.2023)

[3] PM_Volkswagen_Group_and_Gotion_High-Tech_team_up_to_industrialize_battery_cell_production_in_Germany.pdf (Download 09.10.2023)

[cs 09.10.2023]

Group14 Technologies [↑] [↓] [⇑] [⇓]

US start-up for anode material, founded in Washington State in 2015. The powder marketed under the brand name SCC55TM consists of a mixture of silicon and graphite, which is said to have a capacity 5 times higher than pure graphite. The material can be used to increase the energy density of the anode by 50% [1].

Little is known about the technical details, e.g. it remains unclear what measures are taken to prevent the anode from expanding when lithium ions are stored. A sample process has been designed for the production of the material, on the basis of which production facilities are planned all over the world.

Group14’s technology partners include BASF, Porsche, SK Materials. Porsche also has a financial stake in Group14.

The German cell manufacturer Cellforce – now wholly owned by Porsche – announced in 2022 that, following an intensive review process, Group14 Technologies had been selected as the manufacturer of the most promising silicon anode material for Porsche’s requirements. According to Markus Gräf, Managing Director of the Cellforce Group, “… the anode material from Group14 has game-changing potential on the road to shorter charging times” [2].

Molicel, a Korean manufacturer of high-performance cells, announced in May 2024 that Group14 had been selected as a new supplier of anode material [3].

Sources

[1] https://www.group14.technology/ (Homepage, Access 01.06.2024)

[2] https://www.cellforce.de/2022/05/10/kooperation-mit-group14-technologies/ (Access 01.06.2023)

[3] https://www.group14.technology/resources/press-releases/group14s-silicon-battery-material-enables-breakthrough-power-and-charging-performance/ (Access 01.06.2023)

[cs 01.06.2024]

Gus Technology [↑] [↓] [⇑] [⇓]

Taiwanese start-up for lithium–ion cells, which was founded in 2017 by materials scientists; fields of application are energy storage systems and electromobility [1].

Gus produces pouch cells with the well-known cell chemistry variants NMC and LTO as well as with a self-developed cell chemistry called AS200.

Gus is a contract manufacturer for the Slovakian start-up Inobat.

Sources

[1] https://gustech.com/ (Homepage, Access 09.10.2023)

[cs 10.10.2023]

English start-up for innovative lithium–ion cells, which was spun off from the University of Southampton in the south of England in 2004. Ilila develops solid-state cells with a silicon anode, a solid electrolyte and a conventional NMC or LFP cathode. The company is currently producing sample cells in pouch format, which will soon be evaluated in automotive projects [1].

At 250 Wh/kg, the current cells achieve the energy density of conventional NMC cells.

Sources

[1] https://www.ilika.com/ (Homepage, Access 02.07.2024)

[cs 02.07.2024]

US start-up for lithium–ion cells, which was founded in the state of New York in 2017; fields of application are energy storage systems and electromobility. The Biden-Harris administration’s Inflation Reduction Act [1] was a key trigger for the company’s foundation.

iM3NY plans to produce prismatic cells with a proprietary cell chemistry BM.LMP, which combines the advantages of NMC and LFP and does not require cobalt or nickel. The cell chemistry is based on research by Stanley Whittingham, one of the three winners of the 2019 Nobel Prize in Chemistry for lithium-ion cells [2].

iM3NY has supply contracts with 230 suppliers, whereby it is emphasised that none of the suppliers are from China.

Production will start in Binghamton in the state of New York in September; the plant is designed for an annual capacity of 1 GWh.

Further production sites are planned in Australia and elsewhere, with a medium-term production capacity of 38 GWh per year being targete

Sources

[1] https://im3ny.com/ (Homepage, Access 11.10.2023)

[2] https://cleantechnica.com/2022/09/23/imperium3ny-battery-factory-begins-commercial-production (Access 09.11.2023)

[cs 11.10.2023, 09.11.2023]

Swiss start-up that has developed a non-organic, liquid electrolyte for lithium–ion cells, i.e. an ion-conducting liquid without carbon compounds. The company was founded in 2018 and now also has a site in Bruchsal, Germany.

The electrolyte is marketed under the name I-STATE. According to the company, the product offers advantages over organic electrolytes in terms of chemical stability, temperature range (down to -60 degrees) and can be used with different cell chemistry variants.

Technology partners include the Karlsruhe Institute of Technology (KIT) and the electric aircraft start-up Vaerdion.

Sources

[1] https://www.innolith.com/ (Homepage, Zugriff 14.07.2023)

[cs 14.07.2024]

Slovakian start-up for lithium–ion cells, which was founded in 2019; envisaged fields of application are energy storage systems and electromobility [1].

Gotion High-Tech has held a 25% stake in Inobat since September 2023; Inobat has commissioned the Taiwanese start-up Gus Technology with cell production to supply the Asian market.

Inobat develops and produces pouch cells and prismatic cells; NMC622 chemistry is used for Generation 1.

Inobat sees itself more as a producer of customised cells and less as a high-volume producer of standard cells.

In November 2023, the German eVTOL start-up Lilium announced a cooperation with Inobat. The Slovakian start-up will produce cells for the Lilium Jet at its first production facility “Volta I” and will also build a second production facility with an annual capacity of 4 GWh to supply Lilium.

Sources

[1] https://www.inobat.eu/ (Homepage, Access 09.10.2023)

[2] https://lilium.com/newsroom-detail/lilium-announces-partnership-for-high-volume-production-of-lilium-jet-battery-cells (Access 05.12.2023)

[cs 10.10.2023, 05.12.2023]

Ion Storage System [↑] [↓] [⇑] [⇓]

US start-up for innovative lithium–ion cells, which was founded in 2015 on the East Coast in the Baltimore metropolitan area. Investors and partners of Ion Storage System (ISS) include the Advanced Research Projects Agency (ARPA), Lookheed-Martin, Toyota Ventures and the French Saint-Gobain Group [1].

Anode and separator technology from Ion Storage System based on ceramic materials

(Mit freundlicher Genehmigung/Courtesy of Ion Storage System [Homepage])

ISS is developing lithium-ion cells with a ceramic anode with a porous sponge structure (see figure).

The ceramic material is also used for the separator, i.e. the sponge structure is applied directly to the separator, which consists of a non-porous ceramic plate (see figure). During the charging process, the cavities in the lithium-ion or lithium are filled.

According to ISS

- the ceramic material prevents the formation of dendrites,

- is dimensionally stable during charging, i.e. it does not expand, and

- is non-flammable.

ISS does not develop the cathode itself. According to ISS, its anode and separator can be combined with all common cathode variants such as NMC. However, ISS technology is also said to be compatible with innovative chemical variants such as sulphur-lithium.

Cells with ISS technology should be able to be operated in all temperature ranges without a cooling system, be capable of fast charging and have a high energy density.

We did not find any specific performance data on the website, nor any information on pilot projects with the automotive industry.

In May 2024, there was a press event for the opening of a production facility in Beltsville, Maryland. A production volume of 1 MWh is planned for 2024, which is to be successively ramped up to 10 MWh in 2025 and 500 MWh in 2028 [2].

Sources

[1] https://ionstoragesystems.com/ (Homepage, Access 09.07.2024)

[2] https://www.prnewswire.com/news-releases/ion-storage-systems-commissions-one-of-the-countrys-largest-solid-state-battery-manufacturing-facilities-302136731.html (Access 09.07.2024)

[cs 09.07.2024]

US start-up for innovative lithium–ion cells, which was founded in 2019 under the name Zenlabs. The start-up funding came from public and private investors, such as Ford and GM. In 2022, the German eVTOL start-up Lilium participated in a financing round [1].

Ionblox develops cells with a silicon-doped anode that is additionally enriched with lithium.

The first product is a pouch cell with a graviometric energy density of 340 Wh/kg and a volumetric energy density of 850 Wh/l at a weight of 121 g; these cells are to be used in eVTOLs and drones [2].

Sources

[1] https://www.ionblox.com/ (Homepage, Access 05.12.2023)[2] https://static1.squarespace.com/static/63190e90c434457ccb22d15b/t/6358ac15cd41b40fdec473ea/1666755605307/AV+Product+Sheet_IB+2022.pdf (Access 05.12.2023)

[cs 05.12.2023]

Italian start-up for lithium–ion cells, fields of application are energy storage systems and electromobility. Italvolt’s partners include ABB, among others.

It is aiming for an annual capacity of 45 GWh from 2025..

Sources

[1] https://www.italvolt.com/ (Homepage, Access 11.10.2023)

[cs 11.10.2023]

LG Energy Solution [↑] [↓] [⇑] [⇓]

Korean manufacturer of lithium–ion cells and battery systems, which was spun off from the electronics group LG in 2020. Fields of application are energy storage systems and electromobility [1].

LG ES is currently the world’s second largest manufacturer of lithium-ion cells with a market share of 20% in 2023, although BYD has a significantly higher growth rate and will probably overtake LG in 2024 [2].

A production capacity of 300 GWH is planned for 2023 [3].

Pouch Cells from LG Energy Solution

(Mit freundlicher Genehmigung/Courtesy of LG Energy Solution Europe GmbH [Homepage])

Product Portfolio from LG Energy Solution

(Mit freundlicher Genehmigung/Courtesy of LG Energy Solution Europe GmbH [Homepage])

According to LG ES, customers and partners include Audi, BMW, Ford, GM, Hyundai, Kia, Mercedes–Benz, Renault, Stellantis and Toyota [1].

In particular, LG ES is also a technology partner of GM in the Ultium project, in which 3 cell factories are planned in the state of Michigan.

LG ES produces pouch cells in various formats as well as modules, packs and battery management systems (BMS).

LG ES conducts research into solid state cells and lithium sulphate cells.

Sources

[1] https://www.lgensol.com/de/index/ (Homepage, Access 11.10.2023)

[2] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 09.11.2023)

[3] https://www.energy-storage.news/lg-energy-solution (Access 09.11.2023)

[cs 11.10.2023, 09.11.2023]

US start-up for graphene-based high-tech materials and innovative lithium–ion cells. Lyten was founded in 2015 and develops so-called 3D graphene material, which is marketed under the trade name “Lyten 3D Graphene “TM. Partners and investors include Honeywell, FedEx and Stellantis [1].

Lyten uses its specially developed 3D graphene to produce lithium-sulphur batteries, lightweight composite materials and sensors, which are primarily used in the automotive and aerospace industries.

Lyten recently surprised the market by acquiring several assets from Northvolt, the Swedish cell start-up that went bankrupt in 2024.

Graphene is a single layer of carbon atoms with a honeycomb, hexagonal structure. Andre Geim and Konstantin Novoselov were awarded the Nobel Prize in Physics in 2004 because they were the first scientists to succeed in producing graphene in the laboratory. However, the theoretical concept of graphene was already described in the 1940s.

Graphene has very interesting properties. It is a very good conductor of electricity and, despite its extremely thin structure, is up to 100 times stronger than steel. At the same time, it retains a high degree of flexibility.

Graphene is impermeable to almost all gases; only hydrogen and helium can penetrate graphene due to their very small molecules. Graphene is impermeable to water, whereas graphene oxide is not.

As the name suggests, Lyten has succeeded in transforming the originally two-dimensional graphene into a three-dimensional structure. Lyten’s material is to be used in the aerospace, aviation and automotive sectors, among others.

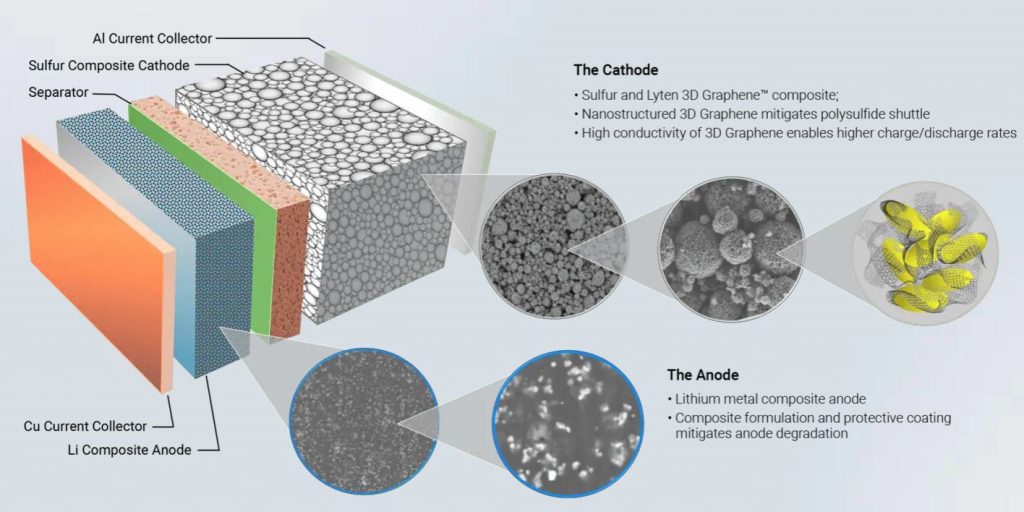

Cell chemistry of Lyten

(Mit freundlicher Genehmigung/Courtesy of Lyten Inc. [Homepage])

Lyten has acquired almost all of Northvolt’s key sites through acquisitions in 2024 and 2025, including the Cuberg plant in California, the energy storage facility in Gdansk (Poland) and Northvolt’s BESS product portfolio with associated intellectual property rights and teams.

In August 2025, Lyten also agreed to acquire the Ett production facility in Skellefteå, the laboratories in Västerås (both Sweden), the planned factory in Heide (Germany) and all remaining IP rights.

Lyten has not yet communicated the strategy behind the Northvolt takeover. In the past, Northvolt and Lyten have addressed different target markets with different technologies:

- Northvolt targeted the high-volume automotive market with its standard NMC technology.

- Lyten addresses graphene-sulphur cells in niche markets such as aviation.

On the one hand, Lyten could use the Northvolt plants to set up NMC production lines for the automotive sector. Alternatively, the plants could also be used for the production of graphene-sulphur cells. A combination of both options also seems possible.

Lyten uses its own graphene material for the cathode together with a sulphur-lithium compound. Lithium-metal composite technology is used for the anode (see figure).

Lyten uses a specially developed liquid electrolyte in its lithium-sulphur batteries, which is stabilized with the 3D graphene. This keeps the sulphur firmly bound, prevents unwanted side reactions and makes the battery more powerful, safer and longer-lasting [2].

Lyten produces sample cells in pouch and round format on a pilot line in San Jose, including round cells in 18650 format. According to Lyten, the cells can be produced using standard processes and achieve an energy density of up to 275 Wh/kg [2].

The main advantages of Lyten cells are said to be the lower costs and the lower weight. As the cathode does not require heavy minerals such as nickel, manganese and cobalt (NMC) or iron and phosphorus (LFP), this results in a weight reduction of up to 50 % compared to NMC cells and up to 75 % compared to LFP cells. Similar values are achieved for the anode.

Sources

[1] https://lyten.com/ (Homepage, Access 14.07.2024)

[2] https://powersourcesconference.com/PowerSources23/docs/15-4.pdf (Zugriff 20.08.2025)

[cs 14.07.2024, 20.08.2025]

Taiwanese manufacturer of lithium–ion cells, which was founded in 1977 and is now part of the Taiwan Cement Corporation Group; fields of application are energy storage systems and electromobility [1].

Molicel produces lithium-ion cells, the only design format is the round cell or cylindrical cell. So-called high-power, medium-power and energy cells are manufactured.

Molicel’s customers include the Wiliams Formula 1 team and the eVTOL start-ups Archer Aviation und Vertical Aerospace.

Sources

[1] https://www.molicel.com/ (Homepage, Access 09.11.2023)

[cs 09.11.2023]

Morrow Batteries [↑] [↓] [⇑] [⇓]

Norwegian manufacturer of lithium–ion cells, which was only founded in 2020 and whose shareholders include ABB, Siemens, the Danish pension fund PKA and a number of Norwegian funds [1]. The initial field of application is energy storage systems, with electromobility to be added later.

Morrow is planning the production of lithium-ion cells in prismatic format, with the production of LFP cells due to start in 2024. Other cell chemistry types are to be added from 2025, with an annual volume of 43 GWh targeted for 2028.

Sources

[1] https://www.morrowbatteries.com/ (Homepage, Access 12.11.2023)

[cs 12.11.2023]

US start-up founded in 2012; its website lists Ford and GM, among others, as partners. Nanograf has developed a patented anode material with a high silicon content (approx. 25%), which can be easily integrated into existing production processes for lithium-iron cells.

According to Nanograf, it can be used to produce 18650 round cells with a volumetric energy density of 810 Wh/l.

We were unable to find any more specific information on current or planned projects on the website.

Sources

[1] https://www.nanograf.com/ (Homepage, Access 12.11.2023)

[cs 12.11.2023]

Former Swedish start-up for lithium–ion cells, founded in 2017 by former Tesla managers Peter Carlsson and Paolo Cerruti. Shareholders included BMW, Goldman Sachs, Volvo and VW. The main fields of application were electromobility and stationary energy storage systems.

The company pursued ambitious plans: by 2030, an annual production of 150 GWh was to be achieved with four gigafactories. The first production facility “Ett” in Skellefteå (northern Sweden) started with a planned capacity of 16 GWh and exclusively used CO₂-free electricity. Further plants were planned in Gothenburg (50 GWh), Heide (northern Germany) and Montreal (Canada). A plant for energy storage systems (ESS) was also built in Poland.

In 2021, Northvolt took over the US start-up Cuberg, which developed high-energy cells with a lithium anode.

However, despite prominent investors, Northvolt ran into massive financial difficulties in 2024. In November, the company filed for Chapter 11 bankruptcy protection in the USA, followed by insolvency in Sweden in March 2025 – the largest in Swedish industrial history.

The main cause is considered to be hasty expansion: Northvolt tried to implement several major projects at the same time, develop new cell chemistries and control the entire value chain itself. This strategy led to high costs, delays and financing problems. Critics see this as the main mistake – the company tried to do too much at once and got bogged down.

In August 2025, the US company Lyten took over key sites, including Northvolt Ett (Skellefteå), Northvolt Labs (Västerås) and the planned site in Heide (Germany), and secured the remaining intellectual property rights. As a result, significant parts of Northvolt’s infrastructure and technologies were transferred to Lyten.

Sources

[1] https://northvolt.com/ (Homepage, Access 13.11.2023, 17.08.2025)

[cs 13.11.2023]

US start-up for lithium–ion cells and batteries from Michigan, fields of application are energy storage systems and electromobility. We have not found any information on the shareholders, but One also benefits from the Inflation Reduction Act (IRA) of the Biden/Harris administration [1].

One develops prismatic cells with LFP chemistry and so-called anode–free cells, on the basis of which One builds battery systems for trucks, cars and energy storage systems (ESS). In the so-called Gemini battery, both cell types are even installed in one battery.

One emphasises that the supply chain only includes North American companies.

In November 2023, production was ramped up at the only plant in Michigan to date. The maximum volume of 200,000 batteries is to be reached in 2027.

There is no specific information about One’s customer base on its website, and research on the internet is difficult due to the name.

Sources

[1] https://one.ai/ (Homepage, Access 13.11.2023)

[cs 13.11.2023]

OneD Battery Science [↑] [↓] [⇑] [⇓]

US start-up for the anode material of lithium–ion cells. OneD produces so-called silicon nanowires, which are mixed with graphite, the main material of the anode. According to OneD, this triples the energy density of the anode. The admixture does not require any changes to the cell production processes and the existing machines can continue to be used.

Karl-Thomas Neumann, a well-known manager in the German automotive industry (VW, Conti, Opel) is one of the early investors and long-standing members of the Board of Management of OneD. GM has held a financial stake in the company since 2022.

In June 2023, a technology partnership was announced with the German small series manufacturer Customcells. Customcells’ customers include Porsche and Lilium, but it is not known whether the sports car manufacturer and the German eVOL start-up will utilise OneD’s technology in their products in the future.

Sources

[1] https://onedsinanode.com/ (Homepage, Access 13.11.2023)

[cs 13.11.2023]

Japanese electronics group founded in 1918; with regard to electromobility, Panasonic became known primarily as an original equipment manufacturer and technology partner of Tesla [1].

The lithium–ion cells business is part of the Panasonic Industrial (PI) division [2]; in 2023, PI was the fourth–largest manufacturer worldwide with a market share of 10% [3]. However, the market share in 2022 was still 11%, i.e. the growth of competitors is higher.

Cells with different formats from Panasonic Industries

(Mit freundlicher Genehmigung/Courtesy of Panasonic Industry [Homepage])

PI produces all cell formats, i.e. cylindrical, prismatic and pouch cells, while Tesla uses round cells in the 18650 (Model S and X), 2170 (Model 3 and Y) and 4680 formats.

PI has failed to win other major customers for its cells in addition to Tesla and is therefore heavily dependent on Tesla. When Tesla announced in Q3/2023 that it was reducing the production capacity of the Model S and X, this had a direct impact on the production volume of 18650 cells.

Of course, PI is also researching new cell technologies such as the solid-state cell [4].

In December 2023, Panasonic announced a technology partnership with Sila Nanotechnologies, the US manufacturer of a silicon-enriched active material for anodes. Panasonic will use Sila’s material in its US plants in the future. The aim is to increase the volumetric energy density of the cells from 800 Wh/l to 1000 Wh/l.

Sources

[1] https://www.panasonic.com/global/home (Homepage, Access 15.11.2023)

[2] https://industrial.panasonic.com/ww/products/pt/lithium-ion (Homepage, Access 15.11.2023)

[3] https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world (Access 15.11.2023)

[4] https://news.panasonic.com/global/topics/5314 (Access 15.11.2023)

[5] https://news.panasonic.com/uploads/tmg_block_page_image/file/20900/en231212-3-1.pdf (Access 15.12.2023)

[cs 15.11.2023, 15.12.2023]

PowerCo SE is a European company (Societas Europaea) based in Salzgitter/Germany, owned by Volkswagen AG [1].

In future, PowerCo will produce the so-called “unified VW cell” for all brands in the VW Group. This is a prismatic lithium-ion cell that can be produced with the cell chemistry variants NMC and LFP. In the future, 80% of all BEV models in the VW Group will be equipped with this unit cell.

The first production facility, called Salzgiga, will be built in Salzgitter and production is scheduled to start in 2025. The annual production volume is 40 GWh, which will enable the production of 500,000 BEV vehicles. Salzgiga is the model for further factories in Spain (start of production in 2026) and Canada (2027); VW also uses the concept of globally standardised production facilities in vehicle construction.

In total, 6 factories with a total volume of 240 GWh are to be built by 2030. In comparison: CATL is planning a volume of 800 GWh in 2030.

VW Standard Cell from PowerCo installed in a Battery-Pack

(Mit freundlicher Genehmigung/Courtesy of Volkswagen AG [Homepage])

The unifed VW cell is around half the length of BYD‘s Blade cell, which is probably due to the desire for greater flexibility. The cells can therefore also be used to build batteries for lorry tractors, which are typically placed where the tank is currently located. The blade battery would be too long for this approach.

Compared to other prismatic cells, the electrical connections in the unit cell are installed on the narrow side so that both large side surfaces can be cooled. The pressure relief valve vents gases downwards so that passengers are not endangered by hot gases [2].