Surprise: Lyten takes over former Northvolt plants!

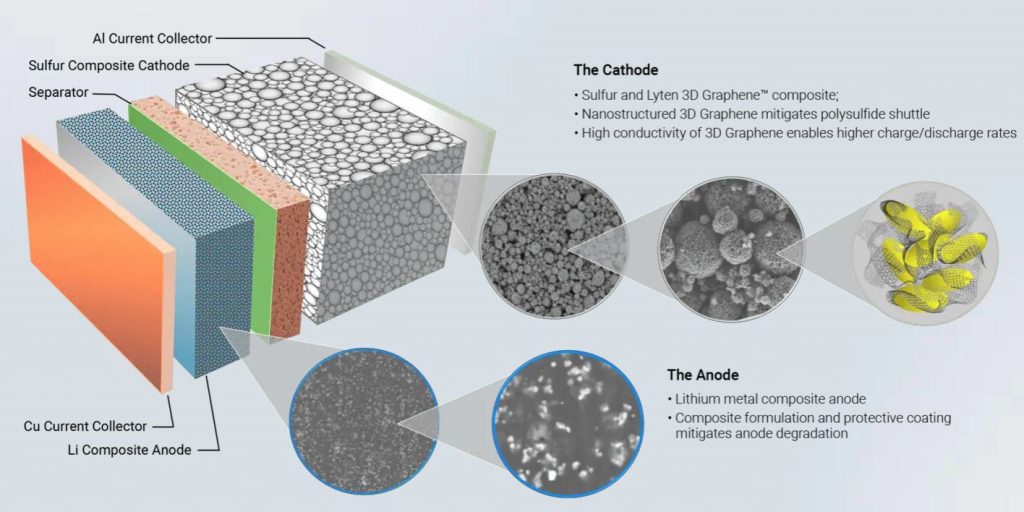

Cell chemistry of Lyten

(Mit freundlicher Genehmigung/Courtesy of Lyten Inc. [Homepage])

The recent news that the US company Lyten will take over almost all of the sites of the insolvent Swedish cell start-up Northvolt came as a surprise. This was surprising because Northvolt and Lyten had previously been targeting completely different markets with different technologies:

While Northvolt wanted to serve the high-volume automotive market with its NMC cells, the US start-up has so far only addressed niche markets such as aviation with its particularly lightweight and innovative graphene-sulfur cells.

How will Lyten use the Northvolt assets in the future? Concrete information has not yet been disclosed. In our view, there are three strategic options:

- Lyten establishes production for NMC cells in all former Northvolt plants and thus enters the automotive market.

- Lyten converts the plants to produce lightweight graphene-sulfur cells.

- An intelligent combination of both variants would also be possible. The existing NMC production lines in Sweden could be used to manufacture automotive cells, while the plant in Heide/Northern Germany, which is still under construction, could be equipped to produce graphene-sulfur cells.

So, what is so special about graphene-sulfur cells? As the name suggests, Lyten uses graphene, which consists of carbon, as the active material. For this purpose, the original two-dimensional material was further developed into a three-dimensional structure.

Graphene originally is a single layer of carbon atoms with a honeycomb, hexagonal structure. It is a very good electrical conductor and, despite its thin structure, is much stronger than steel and yet very light.

In the Lyten cells, the 3D graphene in the cathode is used as a conductive and stabilizing material. This allows the lithium ions to move through the cathode better and with significantly less wear, which also significantly increases the number of charging cycles.

Lyten produces sample cells in pouch and cylindrical format on a pilot line in San Jose, including round cells in 18650 sizes. According to Lyten, the cells can be produced using standard processes and achieve an energy density of up to 275 Wh/kg.

The special feature of Lyten cells is their low weight. As the cathode does not require heavy elements such as nickel, manganese and cobalt (NMC) or iron and phosphorus (LFP), the weight is reduced by up to 50% compared to an NMC cell and by up to 75% compared to an LFP cell.

(cs 25.08.2025)